30+ Years Experience

About SIDVIN Engineering

Precision Component Manufacturer in Bangalore

Welcome to SIDVIN Engineering Pvt. Ltd., a trusted name in precision machining and automotive component manufacturing in Bangalore. With over 30 years of expertise in machining and more than a decade of forward integration in grinding, EFD, and automation, we are a preferred partner to leading global OEMs such as BOSCH, TVS, and Eicher Volvo.

As part of the Chaitanya Group of Companies, SIDVIN builds on a strong foundation of innovation, customer trust, and zero-defect manufacturing. Our state-of-the-art facilities, highly skilled workforce, and deep commitment to quality make us one of the most reliable automotive component suppliers in India.

Our Legacy & Group Strength

- - Started in 1992 with Chaitanya Packaging Industries and expanded into precision machining, casting, and automation.

- - Grew into multiple specialized units: Chaitanya Hi-Tech Engineering, Chaitanya Preci-Tech, Deccan Cast Mac, and now SIDVIN Engineering.

- - Nearly 50+ CNCs, VMCs, and high-end SPMs across 5 units in Bangalore.

- - Trusted supplier of precision parts like plungers, camshafts, housing covers, and valve holders to domestic and international markets.

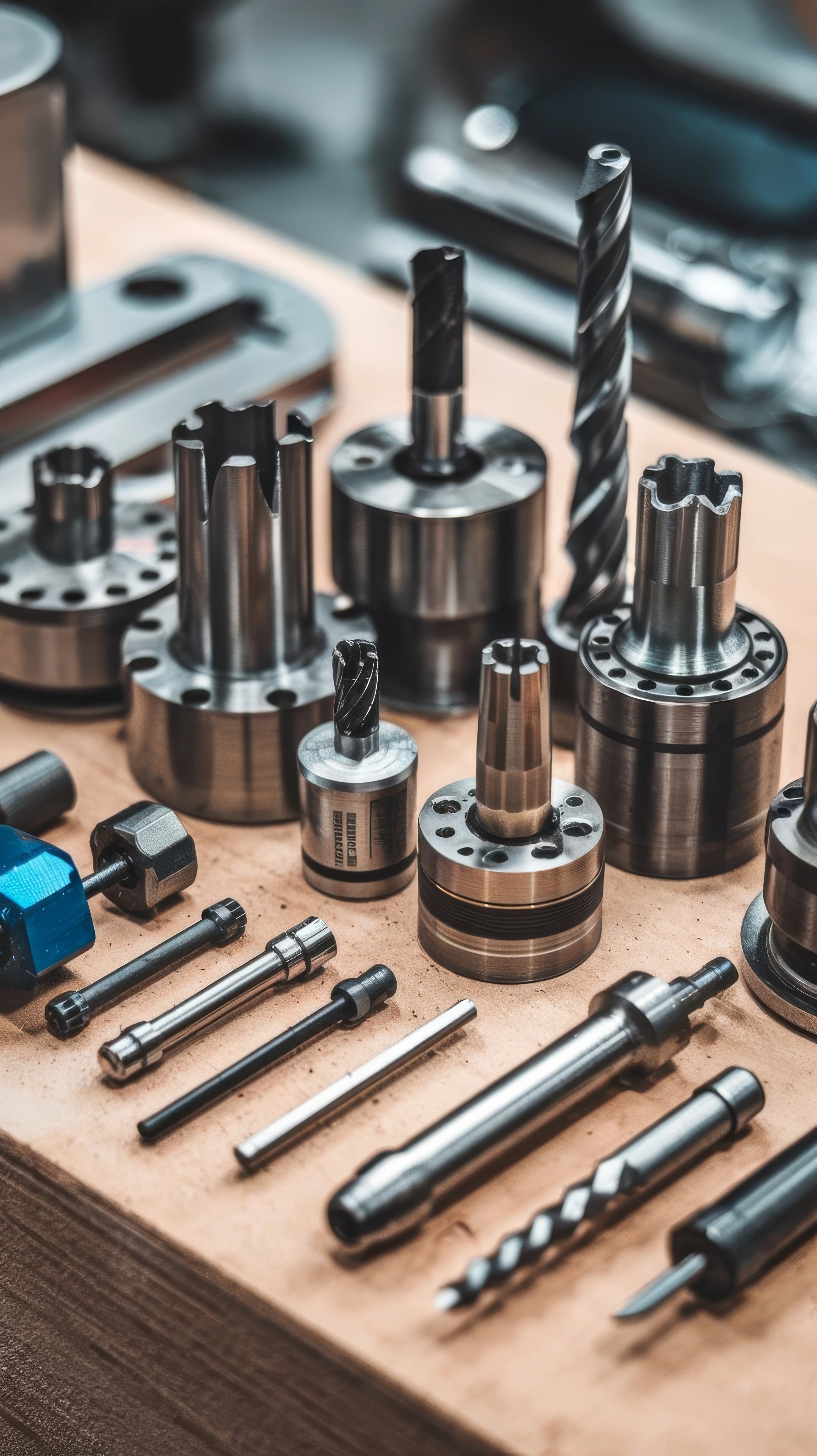

Creative Products

Products We Manufacture

As part of the Chaitanya Group of Companies, founded in 1996 by Mr. H. L. Ramesh Kumar, SIDVIN builds on a strong legacy of innovation, quality, and customer trust. Today, we supply camshafts, crankshafts, valve holders, and precision-engineered components to leading OEMs such as BOSCH, TVS, and Eicher Volvo.

Camshafts

Modern society consumes, consectetur adipisicing elit. Id quae quos cum consequuntur maiores possimus fugiat repellat totam.

Read More

Crankshafts

Modern society consumes, consectetur adipisicing elit. Id quae quos cum consequuntur maiores possimus fugiat repellat totam.

Read More

Valve Holders (CBX & Automotive Applications)

Modern society consumes, consectetur adipisicing elit. Id quae quos cum consequuntur maiores possimus fugiat repellat totam.

Read More

Precision Forging Components

Modern society consumes, consectetur adipisicing elit. Id quae quos cum consequuntur maiores possimus fugiat repellat totam.

Read More

Die-Cast Components

Modern society consumes, consectetur adipisicing elit. Id quae quos cum consequuntur maiores possimus fugiat repellat totam.

Read MoreCapabilities

Advanced Machining & Manufacturing Capabilities

At SIDVIN, we combine state-of-the-art German technology with a robust Quality Management System to ensure zero-defect manufacturing.

We leverage advanced technology and robust processes to deliver high-precision components that meet the most demanding specifications.

- - Next-Generation Machinery : Junker Cam/Shaft Grinding Machines, high-speed RDC machines, VMCs, and CNC automates.

- - Precision Finishing : Ultrasonic finishing, honing, and super-finishing systems for premium results.

- - Backward Integration : In-house aluminum die-casting through Deccan Cast Mac (40,000 sq. ft. facility).

- - Cloud-Based Production Monitoring : Real-time tracking ensures efficiency and transparency.

Infrastructure & Facilities

Our facilities are designed to deliver zero-defect, scalable manufacturing solutions:

SIDVIN operates world-class machining and casting facilities in Bangalore, designed to meet the demanding standards of the automotive industry.

State-of-the-Art Facilities for Zero Defect Manufacturing

Our Facilities Include:

- -18,000 sq. ft. machining plant in Rajajinagar Industrial Town.

- -40,000 sq. ft. casting unit with both pressure die-cast and gravity die-cast facilities.

- -200 KVA power backup for uninterrupted production cycles.

Testing & Measurement Infrastructure:

- -Carl Zeiss CMM for dimensional accuracy.

- -ADCOLE measuring systems for camshaft and crankshaft testing.

- -CNC Vision Measuring Machines for complex geometries.

- -Digital Microscopes for surface and defect inspection.

From concept to completion, we deliver components that fit perfectly Please Contact Us Today

Clients & Partners -Trusted by Global Automotive Leaders

At SIDVIN, quality is more than compliance—it’s our commitment to customers. We follow an ISO-certified quality management system to ensure every component meets international standards.

Long-standing supplier of critical engine components.

Trusted partner for precision

automotive parts.

Supplier of engine camshafts and crankshafts for commercial vehicles